ADE was created in 1985. Its name comes from its three know-how of the time that have evolved today:

|

|

|

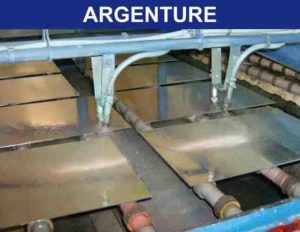

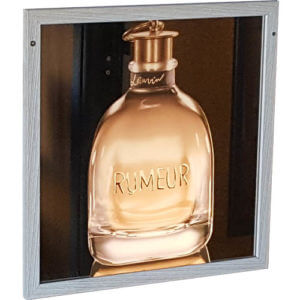

A for argenture (silvering)

Silvering is the transformation of a glass into a mirror.

This transformation involves depositing silver at the back of the glass. A delicate operation and a rare know-how (only 3 companies do it in France) but essential to the realization of a real serigraphed mirror.

|

|

|

How does it work?

| 1. We silver the glass, cut in the format of the mirror | 2. We then protect the silver on the back of the mirror, but only where we want to keep the mirror | 3. We deposit a product that removes silver. The unprotected part will be a transparent glass again | 4. We can finally print the visual on the back of the glass, in the space remained transparent |

|

|

|

|

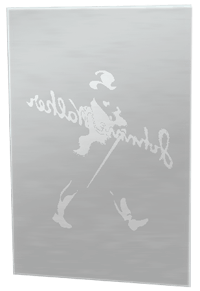

This for 2 reasons:

- You cannot print on the front side of a mirror (the visual would reflect and create an unattractive double effect), so you have to be able to screen the visual between the silver and the glass, which is impossible by directly sourcing mirrors.

- The silkscreened visual between the glass and the silver is visible through the glass, which gives it a magical character: the image is seen by transparency and gives the impression of leaving the glass..

|

|

|

|

|

|

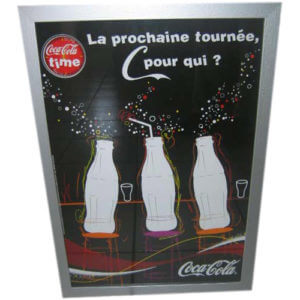

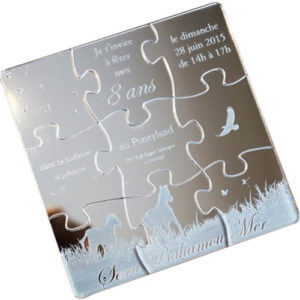

| Made-to-measure mirrors, customizable by the visual, the shape, the size, the frame… | |||||

D for decoration

Decoration at ADE is the printing of media. We will use according to the volume to produce, the desired rendering (…) different techniques.

|

|

|

||

|

|

Screen printing

Screen printing is a printing technique, which involves printing a color after color pattern. This is done using a silk screen, like a stencil interposed between the ink and the support.

How does it work?

| 1. We create our screens that will allow us to apply our colors one by one. These screens are made from a fabric stretched on a frame. We come to plug the mesh of the fabric where we want to block the color to form the pattern to print |

2. We then fix the screen in the screen printing machine. We deposit our ink that is scraped on the screen. The ink passes through the mesh of the fabric (where the fabric is not clogged) and is deposited on the product | 3. After 24 hours of drying, we can switch to the second color if necessary. |

|

|

|

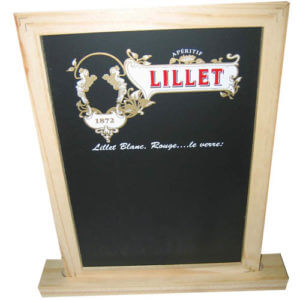

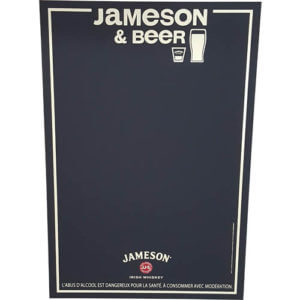

Advantages

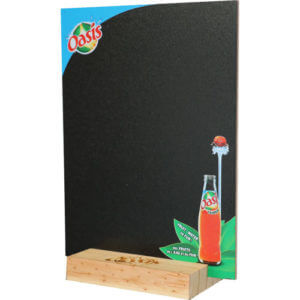

- This is the only technique that can print special inks, such as slate, phosphorescent ink, fluorescent ink …

- Screen printing allows a strong deposit of ink that not only guarantees an intense color that lasts in time, but also a good opacity.

- The costs are very competitive on large series.

Inconvenients

- The time required for the production of screens and the calibration of machines generates costs that are amortized for large series, but can be very expensive on single copies.

|

|

|

|

|

|

| Chalk ink screen printing which can be tinted (here in black, pink or blue), varnish… | |||||

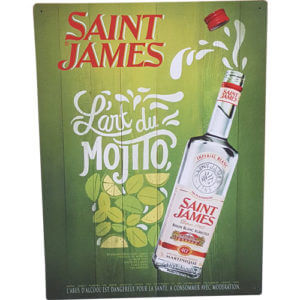

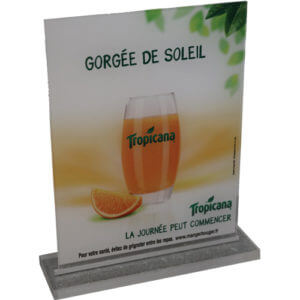

Large format digital printing

Large format digital printing is a modern, efficient and relatively new printing process. This printer has a resolution of 1080 DPI, which allows printing in very large format and with exceptional quality.

|

|

Advantages

- It can be printed individually as in very large series.

- We can print all formats, from small to very large (2 meters wide and unlimited length and up to 5 cm thick).

- All rigid flat supports are printable.

- The ink is dry right out of the printer, production times are short.

|

|

|

|

|

|

| Printing on flexible or rigid materials, from small to (very) large formats. | |||||

Hot stamping

Hot stamping is a technique that heats the substrate in a specific pattern.

|

|

|

Advantages

- We can quickly mark very large series

- The marking is of excellent quality with or without color transfer

|

|

|

|

|

|

| table slate, frame, coin tray, cutting board, cocktail board… | |||||

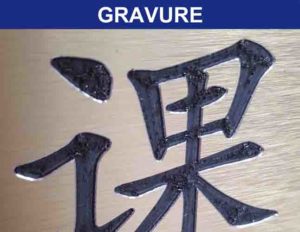

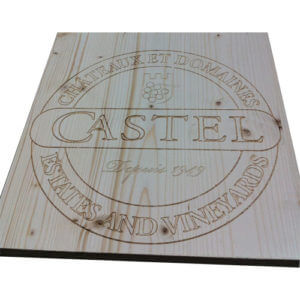

Mechanical engraving

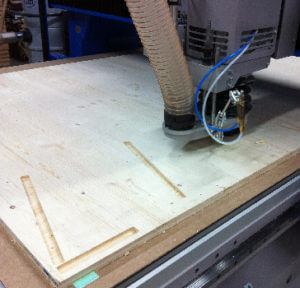

The engraving is performed on the digital machine by the milling technique.

Advantages

- This process allows high efficiency and high accuracy.

- The cut is clean and without burning section.

|

|

|

|

|

|

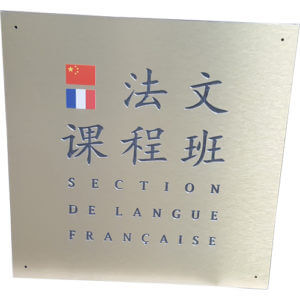

Laser engraving

Laser engraving alters the surface of the material. The laser emits heat high to pulverize the material, forming cavities that will form the final image. This is a fast method, the material being removed at each pulse of the laser. The depth of the marks and the thickness of the line are managed by the number of passes of the beam on the material.

Advantages

- Laser engraving can be used on almost all types of metal, plastic, wood, leather, or glass.

- It is a very precise and more efficient process than traditional engraving, because there is much less risk of damaging or deforming the material.

|

|

|

|

|

|

| trophées plexi, bois, multimatériaux, enseignes … | |||||

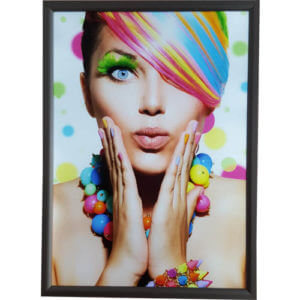

E for encadrement (framing)

Framing at ADE is all that comes to finish the printed product.

|

|

|

|

|

|

|

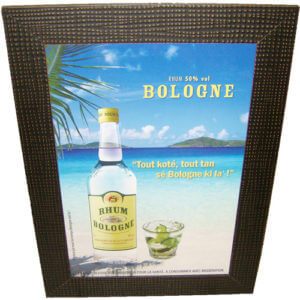

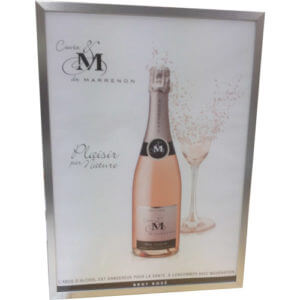

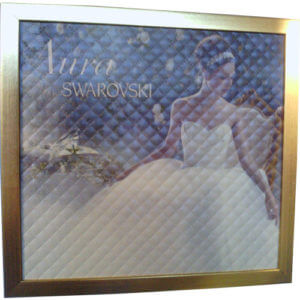

Framing

The frame comes to highlight and protect your support, whether it is a poster, a painting, a canvas, a jersey…

|

|

Advantages

- The frame is cut and mounted in our workshop, which allows you to have a frame to your measure to the millimeter, from the smallest to the largest formats.

- We have in stock more than 300 different baguettes references, but we can also make the rod of your choice to measure. For more details on the different types of sticks that exist, see pages Technical constraints.

|

|

|

|

|

|

Digital cutting on rigid materials

Digital cutting makes it possible to realize many finishes on our supports, going from the engraving to the cutting, through the drilling, the milling…

The supports can be multiple as slate, wood, dibon, plexiglass…

|

|

|

Advantages

- Precise work on a wide variety of media

- Single productions as well as very large series

- A choice of custom sizes, from small to very large format (3 x 1.5 meters maximum).

|

|

|

|

|

|

Digital cutting on flexible materials

Digital cutting allows fast and precise work on the finishes: full flesh cut, half flesh cut, grooving, etc.

The media can be multiple: adhesives, stickers, tarpaulins, canvas, paper, cardboard…

|

|

Advantages

- Precise work on a wide variety of media

- One-off productions as well as very large series

- A choice of made-to-measure format, from small to very (very) large format (1.6 meters maximum width).

|

|

|

|

|

|

| packaging, posters, window stickers, magnets, adhesives, canvas, displays… | |||||

Laser cutting

Laser cutting is a manufacturing technique that involves cutting and etching material with a laser. It can be made on different materials, such as plastic, wood, aluminum, cardboard…

Advantages

- The cut is ultra thin and thus the cutting lines ultra precise, ideal on fine drawings or to assemble parts

- The finish is clean and requires no additional handling: the edges are shiny on the plexi, blackened on the wood …

- The ecological bonus: laser cutting has a lower energy consumption than other cutting techniques, and above all does not leave waste!

|

|

|

|

|

|

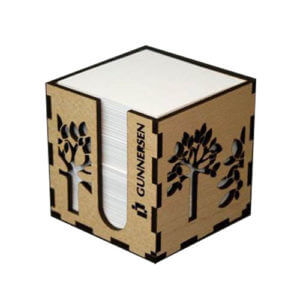

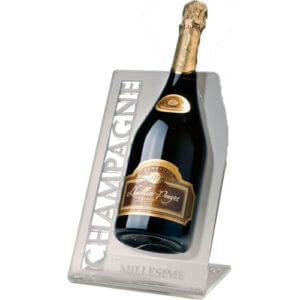

| trophées, cavaliers de pompe, boite et assemblages, lampe, puzzle, présentoir … | |||||

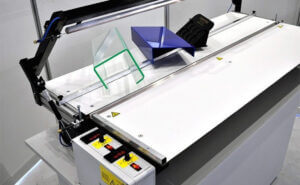

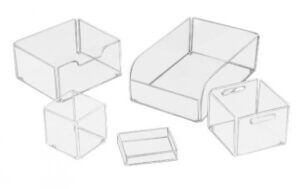

Hot bending

Thermofolding is a method of bending plastic materials carried out by local heating of the part. The material changes from a solid state to a malleable state as it heats up, which allows a bend to be made.

|

|

|

|

|

| The folds can be from the simplest to the most complex: plexi easel with 1, 2, 3 folds, boxes, trays… | ||||

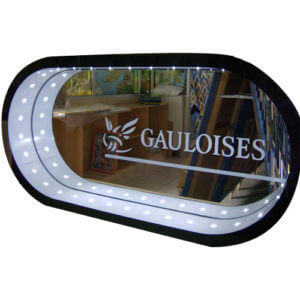

The lighting

Different lighting techniques will be applied according to the desired rendering:

- By neon: the lighting is fixed behind the printed support, in a box.

- By led: the lighting is fixed on the edge of the support (one chooses in this case a luminescent support)

|

|

|

|

|

|

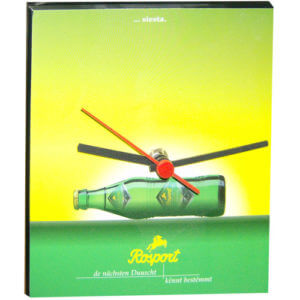

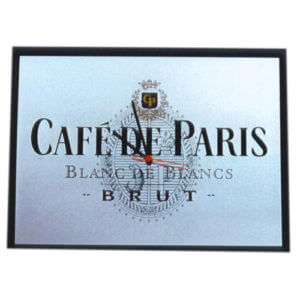

The clock movement

We integrate ourselves the movements of clocks to the supports for 2 reasons:

- It is necessary to print the support before being able to integrate the movement of clock there.

- This allows us to offer clocks on the most varied media (artists’ paintings, mirrors, plexiglass, MDF medium…)

|

|

|

|

|

|

The lamination

Lamination is a process that allows adhesive film to be deposited on posters, placards, signs, adhesives (…) to protect them.

Several types of lamination are possible:

- The front lamination: the film is glued on one side of the document.

- The double-sided lamination: the document is encapsulated in film to protect it from any external aggressions.

- The laminating lamination allows to stick the document to a support and then laminate.

Custom manufacturing

At ADE, we love challenges! For our clients, we are looking for the most varied and crazy projects!

Do you have a project that has never been done before? We strive to find out how we can make what you want. So let’s think up!

|

|

|

|

|

|